How to Determine the Hardness of Rubber Rollers

Hardness of Rubber Rollers

April 2012

Overview

After receiving considerable positive feedback on my last article sharing a conversation with a customer, we decided to share another. This article summarizes a series of exchanges recently with a customer about something that might appear rather mundane, but turned out to be very enlightening for him, and we hope for others as well. The topic of our conversation was "Rubber Hardness" and how to determine the hardness of rubber rollers. This includes a discussion of ASTM guidelines, tools for measuring rubber hardness, and several reasons why this topic is so critical to process control. We also discussed how Imperial Rubber Products adheres to tighter standards than the industry norms.

A Conversation with a Customer Takes a Turn

A customer recently returned my call notifying him that a roll we were producing for his company was going to take a couple days more to deliver than we had initially discussed. He naturally inquired as to the reason for the change in plans and I explained that the hardness of the roll didn't meet our specifications.

He wanted more information about this and asked, "What is the standard for the industry?"

My reply was that, "the industry standard for hardness of rubber is plus or minus 5 points, so there's a 10 point range."

And he said, 'Well, the magnitude of the variation allowed by that specification may be affecting my process; I could drive a truck through something that wide."

So I explained that, "Yes, you could. A 10 point range can introduce tremendous variation in the way your system, which is trying to apply a coating to a plastic, is going to react, in response to a force applied."

And so what originally started off as a conversation about why the roll would take a bit longer to deliver, all of a sudden turned into a discussion of rubber hardness and its impact on process control.

"Wow, I had no idea."

ASTM Guidelines for Testing Hardness of Rubber Rollers

So we discussed further what the industry norms allow. I explained that the source of the standard is ASTM D2240, which allows plus or minus 5 points around a target hardness specification, meaning a 10 point range of hardness is acceptable.

"This test method is based on the penetration of a specific type of indentor when forced into the material under specified conditions. The indentation hardness is inversely related to the penetration and is dependent on the elastic modulus and viscoelastic behavior of the material."

[Source: http://www.astm.org/Standards/D2240.htm.]

And he said, "Well if that's not your standard at Imperial Rubber Products, what do you do?"

Tighter Tolerances Than Industry Norms

I explained that our approach is measured on the same scale, but that our standard allows only half as much variation as the industry allows. The result is that on a hardness scale ranging, for example, from zero to 60, we allow for +3 to -2 points, a total range of 5 points; and if the hardness being measured is above 60, we use the reverse. In that case, our acceptance criteria are -3 to +2 points. That's still a range of 5 points on the hardness scale. At Imperial, we control that variance more tightly than the industry norms, so that the response in your system can be more controlled.

Our customer asked what we have to do in order to achieve those tighter standards. My reply was that, when we choose a supplier of rubber, that tighter standard is part of the qualification process, and if they're unwilling to accept that, then we're not going to do business with them. That's because that narrower range is our governing specification for our supply chain, and that's the same standard we hold ourselves to internally. So the people in our supply chain make up a closed loop system.

He reiterated that he wasn't aware that we held the durometer specification so tight.

And he wanted to check the durometer of the rolls in his shop. So he did that and called me back a little later and said, "You know, I went outside and I checked the rolls we have in house. The specification we have from the OEM is that they're supposed to be at 60 durometer. But based on what you're telling me, the rolls we get could be as hard as 62. But the roller actually measured 64, so it's outside of that range. How could that be?"

Durometer Measures the Hardness of a Rubber Roller

Before proceeding further with this story, it's important to make sure that we are clear about a few fundamentals. Let's start with the basic terminology.

First, let's be clear that durometer is the international standard for measuring the hardness of rubber. The hardness of a material is determined as its resistance to surface penetration. The term durometer is often used to refer to the measurement, as well as to the instrument itself.

[Source: http://en.wikipedia.org/wiki/Shore_durometer]

Correct Way to Measure the Hardness of Rubber Rollers

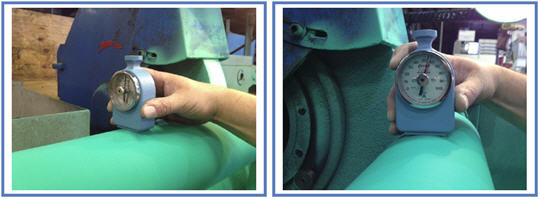

A second fundamental concept to ensure we have clear is that there is a right way and a wrong way to use a durometer to measure hardness.

In the correct way, the base of the durometer is parallel with the axis of the roller.

The wrong way would be having the base of the durometer perpendicular to the axis of the roller.

If you were working with a completely flat surface, that technique would not be critical. But with rollers we're dealing with a curved surface. And such an object has a radius and a center, and these are important considerations.

If you were to turn the durometer 90 degrees from the axis of the roller, it would be rolling onto the durometer base, which provides inaccurate reference data when the durometer makes its measurement.

To avoid this, the base of the durometer, or the base of the instrument, has to be in line with (or following the same line as, or parallel to) the axis of the roll.

As such, an incorrect way to take a measurement of hardness would be if the base of the durometer, or the base of the tool, was actually not parallel to the axis of the roll or the shaft that's holding the roll.

So I sent him photographs that showed different ways of holding a durometer and using it to measure the hardness of a rubber roll.

Held incorrectly one way, the durometer will give a false reading that's too high… and held incorrectly another way, the durometer will give a false reading that's too low.

Another photo I sent him showed the correct way to measure hardness of a rubber roll with a durometer.

Examples of How to Hold a Durometer to Measure Hardness of a Rubber Roller

"INCORRECTLY"

How to Hold a Durometer to Measure Hardness of a Rubber Roller

"CORRECTLY"

In the photo above, the durometer is correctly placed parallel to the axis of the roller being measured

Methods for Measuring the Hardness of a Rubber Roller

Now that we're clear on those key concepts, let's get back to my story.

You'll recall that the customer asked how he could check the hardness of a roll and get a different reading than we did at our shop.

Here I replied, "Well, therein lies a different conversation, where the topics are:

- "What kind of durometer are you measuring?"

- "What is the technique you're using?" and

- "Are you aware of what ASTM says the range should be for different people using different durometers on different types of materials?"

Taken together, these factors present quite a few possible sources of variation in the measurement of hardness of a rubber roller.

So I said to him, "If you'd like, I could come over with the calibrated durometer that we use, and we could check that together."

What we both realized was that his company is not as accustomed to doing durometer checks as we are at Imperial Rubber Products.

Thickness of the Rubber Measured

There's still another factor that can impact results.

We've had discussions where a customer says, "I've measured the hardness on the roll, and it's reading much harder than it should."

And then we say, well your specification on the depth of the rubber you want applied to the roll impacts the measurement of hardness.

Sometimes a customer's application calls for only one-eighth of an inch (1/8") of rubber, and the ASTM specification says that if you're going to make an accurate reading with your durometer, the rubber must be at least one-quarter of an inch (1/4") deep.

That's because, under one-quarter of an inch, the measurement begins to reflect the hardness of the subspace to which the rubber is bonded. And the thinner the roll covering, the more the underlying substrate reflects in the measurement of hardness.

So seeing a measurement above the target specification can be the results of the combination of the hardness of the rubber and the hardness of whatever it's bonded to (the steel or aluminum or carbon fiber material of which the roller is constructed).

Importance of the Hardness of a Rubber Roller

While this article has already considered several important aspects of measuring hardness, it's probably worthwhile to step back and consider why 'rubber hardness' is more important than some people may think it is. Certainly it's obvious that rubber hardness is a key characteristic of a rubber roll. But why is it more important to pay attention to it than some people may think?

The answer can be traced to the reason for having the roller in a production process in the first place.

If the function of a roller is to pull or steer something, then the hardness controls its traction power. To avoid a detailed discussion of 'coefficient of friction' let's just say that as the rubber becomes harder, its traction is reduced. This is much like the rubber tires on a race car.

If you're in a dragster, then at the start of the race, you really want the car to stick to the track. That's because you want to launch off the line. So you don't want those rubber tires spinning. You want the rubber to grab the surface of the road, so you get the maximum possible push forward. And in a drag racing competition, you can't change anything else. You can't change the diameter or size of the tires. So the only thing you can work with is hardness. So going to a softer durometer is better.

That analogy holds in a production process as well.

For somebody working on a critical part of their production process, for example where they need the line to feed something, then having a roller the hardness of a rock means that the roller will slip more. It may need more pressure to pull the material in properly.

If the roller has too much pressure on it, to try to get it to pull, then in situations like the corrugated box industry, that pressure applied to the roller will crush the corrugated flutes of the box, ruining the box.

Another implication is seen in the laminating industry. There you'll see a considerable problem if the hardness of the rubber roller is not within a reasonably narrow range. If the hardness of the rubber roller varies too much, then the pressure the operator applies is varying too much. That means the force on the web or the laminate is going to vary. And that is because the roller is either harder or softer than where it should be. When you don't control lamination of film within a close range (for example with optical products), there may not be enough nip force for the settings and that can result in lamination haze.

A third example would be more relevant for people in the printing industry. If it's an offset application, where a customer's asking for say a 28 durometer roller, and he's doing high graphics printing, or a newspaper industry where he may be a little on the harder side, once the roller reaches a particular hardness range, it doesn't transfer ink properly, and if it doesn't transfer ink properly, then the quality of the image through the plates is not going to be as good and therefore it's not going to be—the corresponding printed surface is not going to be correct.

That can mean that someone has to stop the press and make adjustments to the process. Or in some cases they can make adjustments on the fly. But the worst is where somebody doesn't catch the problem and the printing goes out, and the quality and the resolution aren't as high as their customer requires.

If they're printing in the flexographic method, then the rubber roll acts as a wiper or metering roll, and it's metering ink against an anilox roll. There, the hardness could be in a wide range. For example, a rubber roller might need to have a hardness of 75, and instead it's 65. Here the difference caused by a rubber roller that's too soft means it's not wiping off enough ink. The excessive ink transferred to the printing plate wastes money, may not dry sufficiently and may cause smeared printing or graphics that do not meet the end customer's quality requirements.

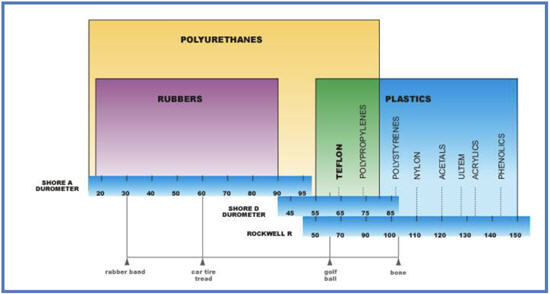

Shore Scale for Measuring Hardness of a Rubber Roller

One thing that might not be commonly understood is the Shore scale. Sometimes people will say a material is 65 Shore A, or Shore D. Let's discuss that for a moment.

Shore is a method by which rubber rollers are tested, and it's named after Albert F. Shore, who developed a measurement device called a durometer in the 1920s.

This instrument has a spring-loaded foot on it, and the pressure of the spring and the sharpness of the foot dictate which scale the durometer is being used on. [A useful illustration of indentor shapes and detail of spring tensions can be found at http://www.rexgauge.com/content/tech_reference_guide.]

So most conventional rubber products in the roller industry – printing, laminating, coating – work on the Shore A scale, which runs from 0 to 100. The higher the number, the harder the material.

But the accuracy of a single durometer scale is not true over the full range of materials we might want to measure. ASTM has done many studies which indicate that at certain points on the hardness continuum, when you've reached a point on the higher side, you should be using a different scale that better reflects a different range of materials.

While there are many different scales, we focus on A and D as they are the ones most commonly used on the rubbers and polyurethanes utilized in the covering of rollers for industrial and graphic arts use. For detailed information on the Shore scales see http://en.wikipedia.org/wiki/Shore_durometer and the charts below.

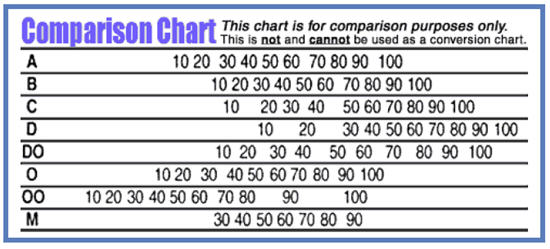

Numerical Comparison of Shore Scales for Measuring Hardness

Source: http://www.rexgauge.com/content/tech_comparison_chart

Graphical Comparison of Shore Scales for Measuring Hardness

Source: http://www.plasticsintl.com/polyhardness.htm

Another scale for hardness that is very common, mostly to the paper industry, is called the P&J plastometer scale, and its range is from 0 to 300. Here the scale is the inverse of the Shore A scale for hardness, where 0 would be something equivalent to a bowling ball, perhaps, and 300 would be something very, very soft and squishy. The plastometer is a test measured over a period of one minute whereas a durometer is an instantaneous reading.

While there are charts to convert P&J measurements to Shore A or D, these are not accurate as there is no direct measurement conversion, only an approximation. Many roller companies will use a durometer to check the hardness of a roll specified in P&J and use a conversion chart to compare. The reason most roller companies don't own a plastometer is the price of the instrument itself. Compared to a durometer which may cost $300 to $500, a plastometer is about $2,500 to $3,500.

Using a Plastometer to Measure the P&J Hardness of a Roll Cover

Other Aspects of Measuring Hardness of a Rubber Roller

There are a couple other things that are important for people to understand about the hardness of rubber rollers, which we haven't already covered.

One key thing to note is that temperature makes a big difference.

Most factories don't have a constant, standard temperature. The temperature on the production line varies with the temperature outside. So if the roller has been sitting outside in the cold, and it's 50 degrees out there, then when someone checks the hardness of the roller, it's going to read harder than it otherwise would. That's because the colder it is outside, the harder the rubber will usually act.

And the hotter the roller, such as in the heat of the summer, or due to the heat of a flatbed truck, then the roller is going to be subject to subtle softening, and it will read softer.

To avoid this problem, durometer can be specified at a standard ambient temperature, or in a standard range.

A related problem occurs when measuring the hardness of a roller in process. Sometimes people say that they checked the hardness of a roller in process, and while it's supposed to be 70, it measured 63. In this case, it's like measuring the tire pressure on your car after you've been running at highway speeds for several hours; you're going to get a different reading than if you measure in the cool of the morning after the car has been sitting in the garage cooling overnight.

As it relates to measuring the hardness of rubber, it's important to note that some rubbers are less sensitive to temperature variations than others. For example, silicone exhibits less change in durometer, in response to temperature changes, than other elastomers do.

So depending upon the type of rubber, you could get an erroneous reading and make process-related decisions based on data where the source of the variation isn't the roller, it's the temperature.

Specifying the Hardness of Rubber Rollers

We have conversations with many customers about specifying durometer for their rolls. We find that some customers know what they want. Often they're basing their specification on duplicating the hardness in an OEM specification, or some other source that they've found over time has led to a stable process for what they do.

But many other customers don't know, and sometimes they don't have a known-good spec. This could be because the company where they got their machinery didn't provide ample documentation. And if that company has gone out of business, that's a problem. At other times, customers are trying to affect a change in their system, but they aren't sure whether they need to go harder or softer. In those cases, customers look to us for advice on how varying the hardness of the rubber rollers they use will impact their process.

Wrapping Up our Discussion of Hardness of Rubber Rollers

This article shared a fairly wide range of topics related to the hardness of rubber rollers arising from a conversation with a customer. This led us to cover how to measure hardness, the many factors that impact a hardness reading, and the importance of hardness of rubber rollers in controlling a process related to printing, laminating and converting. We covered some key fundamental concepts such as the definitions of durometer and the Shore scales. And we discussed that Imperial Rubber Products uses a much tighter tolerance for specifying hardness of rubber rollers than is the industry norm.

Discussions with a Qualified Partner

If you'd like to partner with a supplier who can deliver high-precision rolls consistently and on faster turn-around time than other sources, please contact me. Our company is implementing lean manufacturing principles and we're often holding kaizen events to continuously improve the way we create valuable deliverables for our customers. So thanks to this long-time customer, I'm realizing that we often have something new to discuss with customers and potential partners. And I'd welcome the chance to discuss these topics with you.

About the Author

Bob Schwartz is Vice President of Sales at Imperial Rubber Products, Inc. in southern California. He has over 25 years of experience in the roller and associated capital equipment industries, working with customers throughout North America. He can be reached at or (909) 393-0528.

About Imperial Rubber Products, Inc.

Based in Chino, California, Imperial Rubber focuses on manufacturing and reconditioning rollers for demanding applications. These precision products are used by printers, converters and manufacturers to convert, coat, paint, emboss, laminate, and squeegee. These companies typically work with primary materials such as paper, plastic, steel, aluminum, wood, glass, non-wovens, and textiles.

The company offers considerable product development and custom capabilities, fashioning rollers in a wide array of materials including rubber, polyurethane, silicone, nylon, Teflon™, Rilsan™, chrome, and copper. The company's facilities include its headquarters and main manufacturing facility in the southern California city of Chino (about 35 miles east of Los Angeles); a depot with local support in Sacramento, California; and a fleet of local and long-haul trucks. Imperial Rubber was founded in 1989. It is privately held and owned by operating management. Additional information is available at www.imperialrubber.com.

To download a PDF of this article, please click here.

Contact Us

Tell us your question and we'll reply fast!