Rubber Rollers

Selecting the Right Material for Covering Rubber Rollers

May 2012

Overview

This article reviews a series of challenges in selecting the right material for covering a rubber roller.

It explains how the desired parameters can be listed to help establish selection criteria, and provides examples of how to go about that.

The paper also identifies questions to consider (such as what the roll is going to do, what it's going to come in contact with, and how it needs to perform).

We then develop several triangle diagrams to present the material choices available, and to illustrate how different materials address often conflicting priorities.

By using these tools and this methodology, you will see how to improve the likelihood of selecting the right material for covering your roller.

To download a PDF of this article, please click here.

A Customer's Requirements for a Roll Covering

I recently received a phone call from a customer who wanted a roller to do some specific things. While we always strive to meet our customers' requirements, in this case, the things he was asking for were actually in conflict with each other.

So then it became my role to help this customer understand why with rollers, as in other areas of our lives, you can't always get everything you want. More specifically with rollers, sometimes you can't optimize for all attributes and make it work.

And that's what led me to create my triangle diagram.

Over the phone, I had to paint a visual picture he could see in his mind's eye, so I explained the situation this way. I asked him to imagine having a dining room table, and for the purposes of our story it was the shape of a triangle.

Now further, I asked him to imagine each corner of the table representing a specific property he wanted his roller to have. Let's say these criteria are:

- Chemical resistance

- Abrasion resistance, and

- Fatigue resistance

Now if the elastomer (defined below) we're seeking is in this case a tablecloth and the tablecloth covered all three corners of the table, then it would be ideal, because it would do everything.

[An elastomer is a polymer. The term, which is derived from elastic polymer, is often used interchangeably with the term rubber. For additional information, see: http://en.wikipedia.org/wiki/Elastomer.]

The reality is that tablecloths are not ideal. Sometimes they can't do everything we want. Sometimes they can cover two of the three corners completely, but the last corner not so well. So when you do a real good job of covering up the corners that are labeled chemical resistance and abrasion resistance, then the other corner (in this case fatigue resistance) isn't fully covered. This means that attribute is not going to be maximized. So understanding the type of elastomer, and how important that attribute is to the customer's process, we can see how small the tablecloth is in relation to the table.

Conflicting Requirements for a Roll Covering

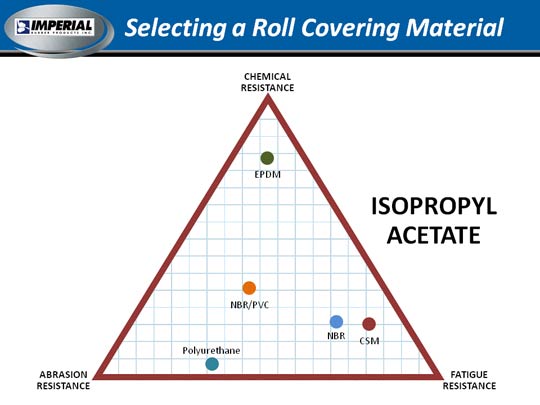

My goal in creating the triangle diagram was to show graphically how the customer wanted a particular material, but he also wanted each of three different attributes to be maximized.

In this case, those attributes were resistance to a chemical, abrasion, and fatigue, and he had to make the roller work with a particular solvent, which the diagram below shows is isopropyl acetate.

So what I did was place in the diagram several different elastomers he had asked me about, and placed them where they would rank in terms of how they would handle each one of these challenges. Then the question became: "Which elastomer is going to be the most useful for covering a roller in his particular application?"

When we focused on the importance of chemical resistance, the diagram shows a green dot representing EPDM as having the highest value. But by selecting that material to cover his roller, its abrasion resistance and its fatigue resistance are nowhere near the other options available to him, towards the bottom of the diagram.

Then we got to discussing abrasion resistance, and its importance to him in achieving a long wearing surface. This was important because this was a roller for a wood-coating application. The problem was that a urethane, which would last the longest, purely from an abrasion standpoint, would not do well with the chemical resistance of the isopropyl acetate, and the customer was forced to use that solvent due to another parameter in his production process.

So what we then discussed was the merits of finding a covering for this roller that is going to be the best balance of all of these priorities.

A Guide to Selecting a Roll Covering Material,

Based on 3 Key Attributes Needed, to Work with Isopropyl Acetate

Selecting the Right Covering for a Rubber Roller

Next we discussed the orange dot in the center of the triangle diagram, which describes NBR/PVC, which is nitrile PVC. It gives him the benefits of a nitrile, and the abrasion resistance of PVC. This material is approximately in the middle of the diagram. So it's not the strongest in terms of abrasion, fatigue, or chemical resistance. But for his application, it's probably the best balance, and that turned out to be the best choice of material to cover a roller for what he was doing.

Actually it turned out that because this customer had other rollers for other applications, the triangle diagram above was one of several that we sent to him.

We had a different diagram to show his material options for covering a roller that would come in contact with MEK, methyl ethyl ketone, another solvent, and then the dots would be in different positions.

So depending on the solvent you're using in your production line, you need to choose a rubber or an elastomer that has the appropriate balance of qualities.

Identifying Critical Attributes for a Roller Covering

At the root of making the right material selection is identifying what the critical attributes are. As discussed above, these could be considerations such as chemical resistance, abrasion resistance, fatigue resistance, or load-bearing ability. It's critical to look at what a given roller actually has to do in the environment that it's going to see, and if there's no chemical resistance involved, maybe that is replaced with some other attribute. [For help identifying the critical attributes for your project, please see "Questions to Ask When Choosing and Designing Elastomers for Rubber Roller Applications" available at www.imperialrubber.com/questions.asp.]

This brings up another customer situation, where I was asked to visit a couple of weeks ago. This company is using the same elastomer on two different machines, and they get different results in terms of product quality and roller life, and they wanted to know why.

First, understand that they're running a similar, or the same, product and one machine was designed and manufactured in-house, but still relatively sophisticated, and was built about ten to fifteen years ago. The second machine is newer. It was engineered and built by another company, and it has a lot more sophistication in terms of construction and other properties.

So then I sat down with our engineer, plus the customer's production manager and process engineer and said, okay, if we're going to select these materials from scratch, then let's identify what we're trying to accomplish, and divide them into three categories. So we created a diagram like the one below, with places to identify and sort out among things that were Must Have, Should Have, and Like to Have.

Identifying and Prioritizing Roller Performance Characteristics

(to help select the proper elastomer)

"BLANK TEMPLATE"

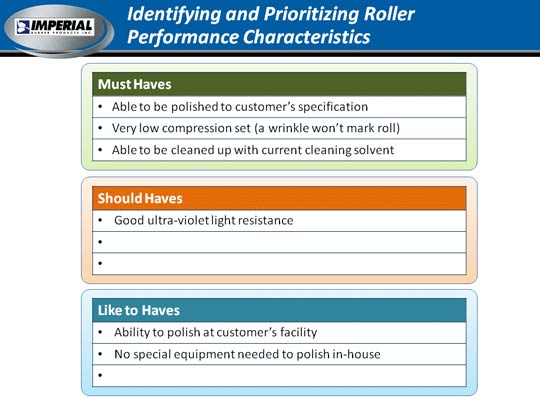

Then I asked, "So what are the Must Haves, the characteristics that this roller must have?"

The customer's people said that it must be able to be polished to a certain level – a very smooth and uniform surface roughness.

It must have very low compression set or very good memory so that it doesn't hold a dent or take a set, or if a little wrinkle goes through there it doesn't mark the roll. That's a Must Have.

They also made it clear that the roll must be able to be cleaned up with their existing cleaning solvent.

Then we continued our discussion, and considered whether each requirement suggested by the customer's team members belonged on the Must Have list. To us this means that no matter what else we do in this conversation, those Must Haves must be met in order to fulfill the proper criteria for this elastomer.

And then we did the same with the Should Haves. Well, one of their people said, I really would like to have good ultra-violet resistance, because it's going to see back-scatter from a UV light. Okay, so UV resistance is a Should Have. What else should it have? So we continued the discussion and built that list.

Then we moved on to the third category. On the Like to Have list, they said that instead of sending Imperial the regrinds all the time, what if they get a little mark on it? They wanted to explore whether they could repolish the roller themselves, and how difficult it would be to repolish in-house. So we put "ease of polishing internally" on the Like to Have list. This customer doesn't have specialized equipment, so that's a characteristic we need to consider; so we put it on the list.

As a result of this conversation, we created a simple chart like the one below.

Identifying and Prioritizing Roller Performance Characteristics

(to help select the proper elastomer)

"EXAMPLE"

Then we revisited the Must Haves and validated that these were indeed that important.

Basis for Recommending the Best Material for Covering a Roller

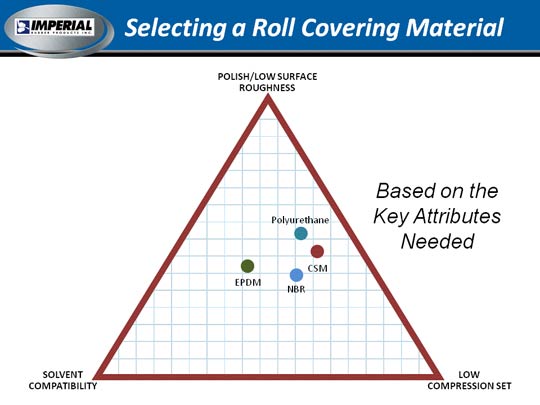

With agreement on direction prioritized that way in collaboration with the customer, I can then say which elastomers are consistent with what we put on the Must Have list. Sometimes it'll happen that none of these may be good on the Should Have, but in this case, there was one that might be.

So the list we created together became the "success criteria" for evaluating the material we recommended for covering their roller.

And as you can see, in this way, we were well prepared to make considerable progress towards meeting the customer's objectives.

When we work with a customer, we certainly want to help the team identify things they can do to improve results, something that's really going to make a difference in their process. And we've found that developing a simple list of priorities like this is a great way to start the process of finding the right material for a customer's application.

Based on the chart developed above, I developed the triangle diagram below, and used it as a tool to explain their options to them. As is often the case in life, there wasn't a convenient way to get everything they wanted. But because we had identified together the list of Must Haves, Should Haves, and Like to Haves… they were able to understand that finding the answer was a matter of balancing multiple priorities, given the physical properties and performance characteristics of the available elastomers. Once we got that on the table, we were able to align ourselves and chart a course to take.

A Guide to Selecting a Roll Covering Material,

(Based on the Key Attributes Needed)

So what we've discussed in this article is how to select the right material for your roller, and how it depends on what that roller is going to do, and what's it going to come in contact with. We discussed how filling out a simple table can help establish priorities, and how a triangle diagram can help assess the available options. Then the team can discuss the pluses and minuses of each of these materials, or elastomers, to cover a roller.

Similar Methodology Applied to a Different Roller & Situation

A different situation would require an additional table, and could result in a different, more complex diagram. For example, let's quickly consider someone working on a high-speed application, and the problem they've been having is rollers blowing up.

That phrase 'rollers blowing up' is often a euphemism for a problem with hysteresis. Hysteresis is the heat build-up within a roll covering from cyclic nip stresses (speed, force, rubber thickness and hardness).

This type of analysis would need a chart with more parameters than just the three corners of a triangle representing speed, load (force) and thickness.

Then we might say that the customer's process demands a particular hardness. Perhaps the customer requires a 70-shore material.

And let's say the customer wants to operate this machine at, let's say, 450 RPM.

So what do they need as a covering material in order to get the roller to run at the designed speed of the machine?

Well, we would look at different dots, representing different elastomers, and place them in different locations inside the triangle.

But you would quickly see that at certain cover thicknesses, at that hardness, with a given material, it's impossible to make that combination of variables work.

This might be a situation where all the dots go into one corner of the triangle, because no matter what you do, at that 70-shore, and at that 450 RPM, an elastomer can't possibly survive the combination of those conditions.

In that case an option to consider is running at a reduced speed, below what the machine was designed to do. But that would lead to reduced output, and therefore lower productivity.

Another option is to choose a hardness and material that causes the hysteresis aspect – the blow-up characteristic – to be reduced.

It is in challenging situations, such as the conflicting priorities in this scenario, where the Imperial team can not only help customers choose the right material to cover their roller, but also help them look at what parameters might be varied, in order to have the best likelihood of achieving their production objectives.

Discussions with a Qualified Partner

If you'd like to partner with a supplier who can deliver high-precision rolls consistently and on faster turn-around time than other sources, please contact me. Our company is implementing lean manufacturing principles and we're often holding kaizen events to continuously improve the way we create valuable deliverables for our customers. And I'd welcome the chance to discuss how we can help your organization improve results.

About the Author

Bob Schwartz is Vice President of Sales at Imperial Rubber Products, Inc. in southern California. He has over 25 years of experience in the roller and associated capital equipment industries, working with customers throughout North America. He can be reached at or (909) 393-0528.

About Imperial Rubber Products, Inc.

Based in Chino, California, Imperial Rubber focuses on manufacturing and reconditioning rollers for demanding applications. These precision products are used by printers, converters and manufacturers to convert, coat, paint, emboss, laminate, and squeegee. These companies typically work with primary materials such as paper, plastic, steel, aluminum, wood, glass, non-wovens, and textiles.

The company offers considerable product development and custom capabilities, fashioning rollers in a wide array of materials including rubber, polyurethane, silicone, nylon, Teflon™, Rilsan™, chrome, and copper. The company's facilities include its headquarters and main manufacturing facility in the southern California city of Chino (about 35 miles east of Los Angeles); a depot with local support in Sacramento, California; and a fleet of local and long-haul trucks. Imperial Rubber was founded in 1989. It is privately held and owned by operating management. Additional information is available at www.imperialrubber.com.

To download a PDF of this article, please click here.

Contact Us

Tell us your question and we'll reply fast!